Insulating your Post Frame Building for Energy Efficiency

There are a number of ways that a post-frame pole barn buildings can be insulated. The most efficient methods are fiberglass, foam, and cellulose, but most important in determining which you use is how you are going to use the building. We are going to discuss three tips to insulate a pole barn that will suit your needs best.

What type of pole barn or post frame building do you need? Is it a garage to store a tractor or other equipment, or is it a man-cave you constructed in your backyard? How you prevent unwanted air movement in and out of your building is important to consider.

Your decision on air flow will translate into the heating and cooling characteristics, noise levels, and the type of ventilation used in your building, not to mention it plays a large roll in separating the indoor and outdoor elements. In the winter months it works to keep the cold out and vice versa, in the summer months it keeps the heat out which is what keeps your properly design pole barn comfortable and saves you money.

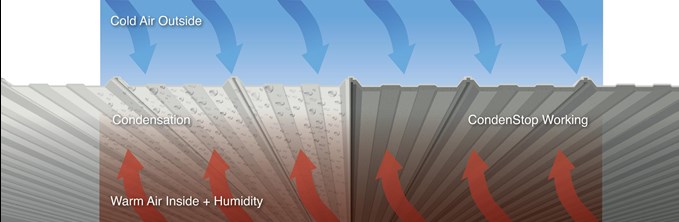

When airflow is not controlled it can create moisture and condensation. As time goes on, this can cause damage like rust, mold, and mildew.

Types of Post Frame Building Insulation Materials

- Fiberglass – for the most part, this has always been the industry standard and it is still the most commonly used material for insulation. It is lightweight and cost effective and you have the option to use a batt or blown form into attic areas. Most construction crews and builders can install batt insulation; when it comes to blown insulation, that requires special equipment, protective gear, and some training.

- Foam – It does a fantastic job insulating a building, but the foam is more expensive. In addition to its expense, it is possible you may have to hire someone outside of the builder to do the insulation.

- Cellulose – This type of insulation also works and is typically used in the attic. It is normally made out of renewable materials and it has a slightly higher R-value per square inch that flown in fiberglass.

1: Determine Your Pole Barn Insulation Needs

When it comes to Pole Barn Post Frame Building Design, the type of insulation you need to use depends on your specific needs. Are going to be working in a garage during mild weather for a couple of hours at a time? You would want to install one or two-inch insulation under the steel. Are you looking to add insulation to your attic? Then you may want to consider the high density of blown cellulose.

2: Consider DripStop Condensation Control

In recent years this has become a popular product. It doesn’t offer much as insulation but it does control condensation. DripStop is a product that works well in warehouse units, animal confinement, or any cold-storage building in which you want to deter moisture.

This particular product is applied directly to the steel. It’s just one third the cost of traditional insulation. It’s a great material if you don’t plan to spend a lot of time in that garage or structure but you want to prevent condensation from forming or dipping onto high-end equipment. If you are a farmer storing tractors as an example, DripStop is a great solution to help protect your equipment. It controls condensation like insulation does but it doesn’t have the additional materials or labor costs to install.

3: Use An Air/Moisture Barrier Layer

If you plan to heat or cool your post frame building, you will want to use some sort of moisture and condensation barrier.

It is important to seal around doors and windows properly to keep both air and water from seeping into your insulation and building materials in your walls.

Proper moisture and air sealing will save you money on utilities and make the air inside your building more comfortable. For a typically constructed pole barn building that has insulated walls, and the structure uses heating and cooling on the interior would need to include a moisture barrier/drainage material on the outside of the building wrap used under the exterior cladding. It is also advised to use a vapor barrier to the inside underneath the interior liner material like drywall, chipboard, paneling, steel liner, etc. on the walls and ceiling.

If the exterior steel is tight and you have no water penetration, then you can insulate your post frame building with fiberglass batt or rigid form without installing a building wrap layer. Rigid foam is not expanding foam but rather pre-formed foam sheets.

There is also one other area that you will need to assess. That would be around the exterior cladding like doors, windows or ventilation. They are often a source for water penetration into a building and they need to be properly sealed.

Post Frame Design & Building Specialists

If you have questions about post frame building design or construction, we invite you to contact us. A Secor post frame building design specialist will be happy to work with you to answer all your questions and help in any way we can. You can reach us during normal business hours at 315-365-2838.

Illustration credit: Fabrel Condenstop